MR-Rotary-damper

Installed in a historic Ferrari

As part of a customer project, INVENTUS replaced existing hydraulic rotation dampers on a valuable, historic Ferrari and implemented 4 MR rotation dampers on the respective wheels.

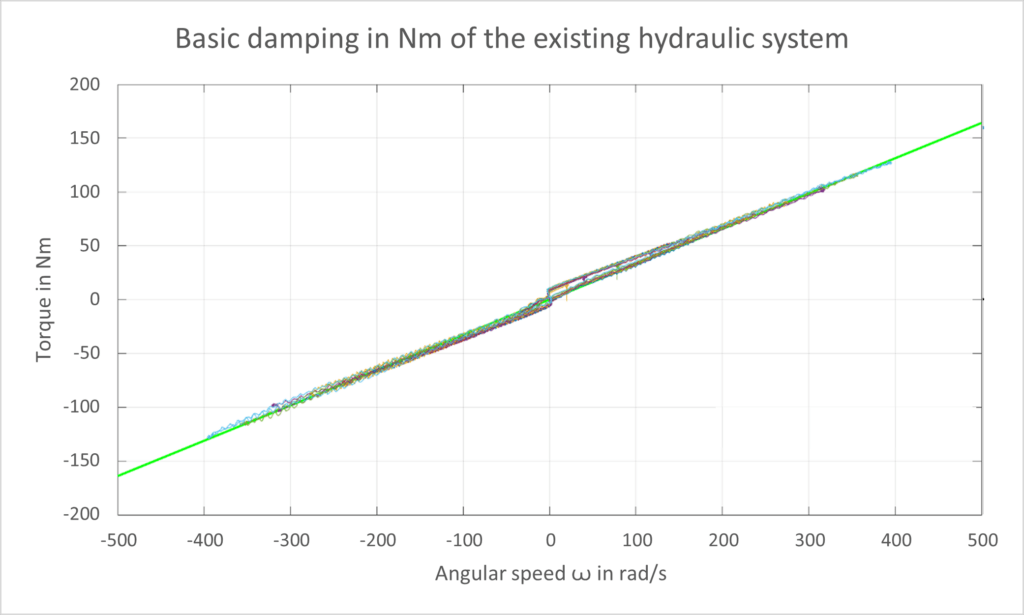

Since the vehicle is a vintage car, certain influences such as the temperature behavior, which has a very strong influence on the basic damping (shown in the diagram below), had to be compensated for by replacing the damper units. In addition, the chassis was not optimally tuned and There were also differences in the spring damper characteristics from front to back or from left to right, which also needed to be compensated/fine-tuned.

These inequalities are due to the fact that the chassis is over 70 years old and the existing leaf springs as well as the replaced hydraulic rotation dampers showed signs of wear. In addition, the aim of this optimization was of course to get the maximum chassis performance.

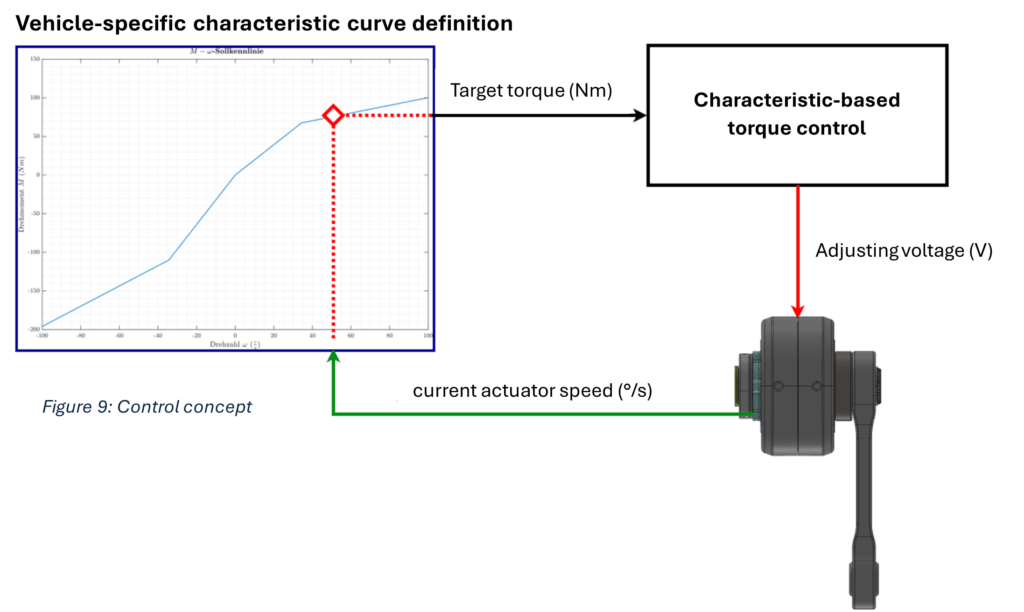

By using the adaptive MR rotation dampers, the system can be adapted as desired to the current situation and fine-tuned accordingly with current control. For example, temperature-controlled viscosity effects can be compensated for or the front or rear dampers can be made softer or harder as desired by the customer – even any chassis adjustment while driving can be implemented.

The following development of the MR rotary damper installed in the historic Ferrari shows the advantages of the MR rotary damper technology and can be used in any other areas of application, e.g. a knee prosthesis, where the present advantages can also be used.

State of the art

Classic hydraulic rotary dampers

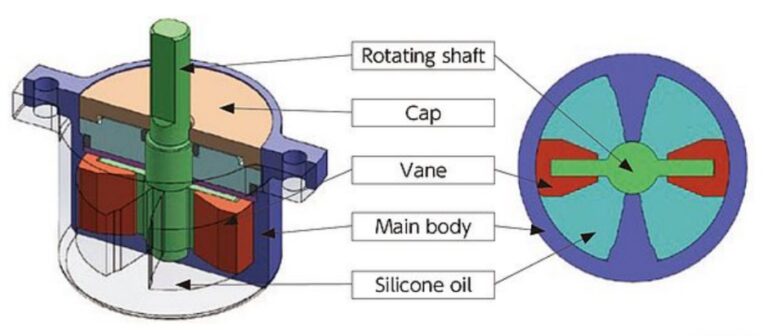

The classic limited angle hydraulic rotary dampers usually have a rotating vane that moves a fluid, usually oil, from one side of a chamber to the other by twisting it. A speed-dependent damping force is created in accordance with the throttle gap.

There are some adjustable/adaptive rotation dampers in which the throttle gap is varied using adjusting elements and the damping torque can therefore be provided within a certain range, but these solutions are not very widespread.

There are also versions for unlimited angles which, like a pump, generate braking torque using hydraulic losses from circulating fluid flows.

Requirements

In order to optimize the chassis performance already mentioned in the introduction, INVENTUS had to fulfill the following specifications with their MR rotation damper:

> Dimensions: diameter 99 mm x Length 110 mm (main body)

> Basic mechanical torque < 3 Nm

> Hydraulic basic torque 50 Nm @ 300°/s | 22°C

> Maximum torque > 140 Nm

> Max. power consumption < 75 W

Solution from INVENTUS

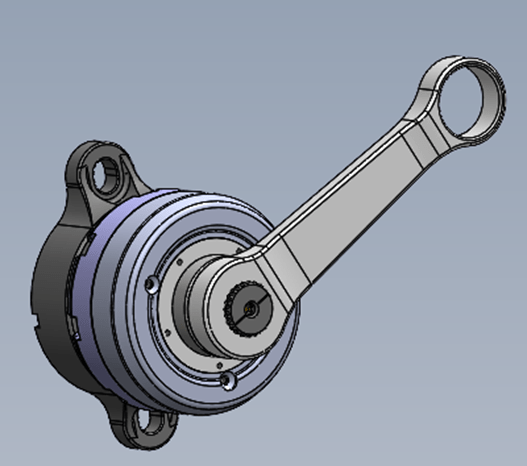

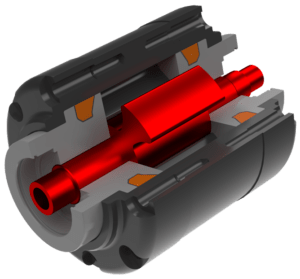

For installation in the historic Ferrari, INVENTUS developed 2 adaptive MR rotation dampers (detailed information) for the front and rear wheel suspensions, which adequately replace the existing purely hydraulic system.

The adaptive characteristic curve control enables a chassis that is individually tailored to the vehicle, driving situation and driving behavior; the speed-based control places high demands on the precision and signal quality of the measured damper stroke/angle. Based on these manipulated variables, end position damping and driving maneuver-specific approaches are implemented at the same time.

How exactly does this application from INVENTUS work?

The adaptive design of the rotary damper creates almost unlimited control and control options, which bring clear advantages in chassis tuning. Where previously the characteristics of the hydraulic rotary damper were implemented in the system in the sense of embedded mechanics and could not be changed, today the damping can be adjusted/regulated in milliseconds become.

Comparison of the state of the art / INVENTUS solution

Basically, the MR rotary damper has 2 significant advantages that result in several positive effects. One is the internal sealing of the MR rotary damper and the other is the operation in a complete working range M(ꙍ, I) instead of being tied to just one characteristic curve M(ꙍ).

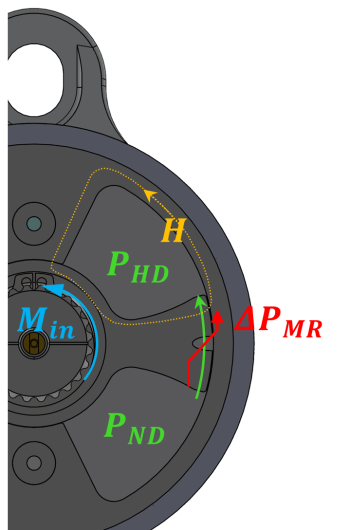

Internal sealing: In principle, sealing the hydraulic rotary damper can be easily implemented, but only outside, inside it becomes very complex and complicated (separation of the complete high-pressure and low-pressure sides: tangential + radial + axial – see the figure below), here they are highly precise Machining processes or maintenance-sensitive seals are necessary. This results in very high costs or limitations in operational/safety and reliability. The big advantage of the MR rotary dampers from INVENTUS is that the magnetorheological effect is used to seal the rotary shaft internally, so no high-precision machining processes are necessary and the system remains almost wear-free and maintenance-free. In order to provide appropriate maximum moments, leakage gaps can be made significantly larger, which simplifies the entire technical implementation.

Benefits of a complete working area: With purely hydraulic rotary dampers, the torque generation is based purely on the hydraulic effect, which has the enormous disadvantage that temperature influences have an extremely noticeable impact on the torque performance. In contrast, with the MR rotary damper, in which the torque is generated by superimposing hydraulic and magnetic effects (see specifications for on- and off-state characteristics), the basic hydraulic torque can be kept very small and the temperature influences are therefore much less noticeable, since The majority of the moment is based on the magnethereological effect, which is hardly independent of temperature.

In addition, the possibility of using a complete work area offers countless advantages in terms of controllability and implementation of various characteristics. Where previously end position damping in the form of a decreasing passage area was implemented mechanically in a purely hydraulic rotary damper, today this can be adjusted, varied or shifted as desired using the current.

Prospect

INVENTUS would be happy to work with you to develop adaptive MR-rotary dampers tailored to your application.