Adaptive Joystick

Manual E-Shifter

In the age of software-defined controls, manual controls are increasingly connected to vehicles/equipment/machines and then enable adaptive and freely programmable control and feedback. This new form of operation creates real emotions in the user and enables a completely new feeling of force feedback. This means that the operator not only gives the control command and a machine/vehicle implements it, but at the same time also gives “feedback” to the operator in the sense of tangible information. You can imagine this, for example, that if an operator wants to realize a certain position of a piece of equipment, a certain position or a certain positioning speed can be stored with a corresponding haptic, or other information such as a load weight can be provided in the form of any feedback passed on to the operator. The times when the display was billed as the “holy grail” of the user interface are now over and many companies are aware that there is no way around intelligent controls, as haptics are simply much more intuitive and impressive than any screen display. Rather, the question arises: How do I build this control element and how do I implement it?

In the following elaboration, the concept of an adaptive joystick is shown using an adaptive/manual e-shifter, but can be used without restrictions in other areas of application.

The video of the E-Shifter below shows how, for example, after deflection, the spring-returned joystick is braked towards the initial point and held in zero position:

State of the art

Analogue joystick

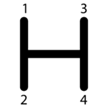

The joystick is a control element that was created as an input device for computer games and is now used in work machines/construction machines, airplanes, motorboats and special vehicles. The 2-axis structure of the analog joystick usually enables a combined movement in the longitudinal and transverse directions, with the swivel angle of the respective axes being recorded by potentiometers and passed on via electrical or hydraulic signals to control various devices. The return is usually done via springs to the starting position.

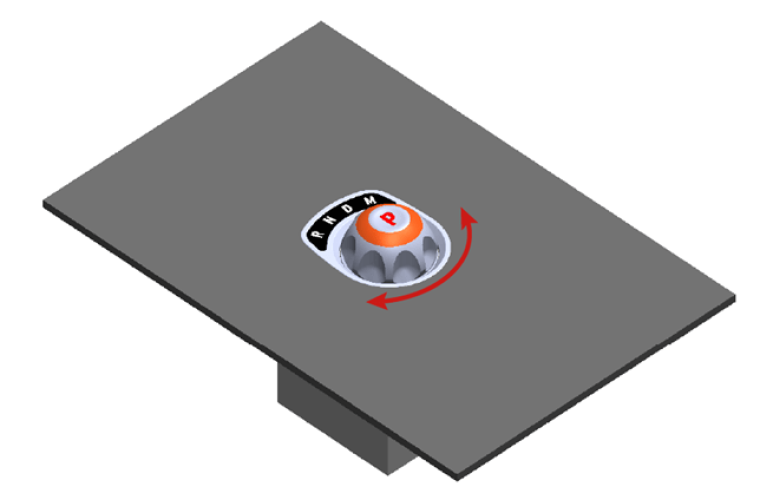

Rotation around Y-axis

Rotation around X-axis

Some joysticks these days are even equipped with a third axis, which also accommodates rotation.

Force Feedback-technology

Force feedback technology again emerged from gaming, in which, for example, bumpy ground or increased control forces in the form of vibrations or sluggishness are passed on to the user as mechanical feedback.

In most cases, this haptic feedback is currently fed back to the control element via electric servomotors, but hydraulic and pneumatic cylinders are also used.

Implementation of the adaptive joystick as an adaptive/manual e-shifter

Electric cars actually no longer require a manual transmission and can get by with a one- or two-speed transmission, which no longer needs to be shifted. However, several well-known car manufacturers are now planning to equip the new generation of electric cars with “fake” gearboxes (e-shifters) in order, on the one hand, to give the driver more driving fun and, on the other hand, to provide clearer feedback regarding the driving experience.

“In a pure electric car with only one gear, no sound and no emotion, you don’t know whether you’re going 120, 150 or whatever,“ van Meel said in the author Motor Sport, considering gear changes essential as driver feedback .

With the aim of coupling software-defined vehicles with manual controls and giving users more driving experience and emotions, INVENTUS implemented an adaptive joystick as an e-shifter.

The following key data was available for the corresponding application:

Maximum locking torque:

Maximum permissible actuation force:

Operating voltage:

Power consumption:

12 Nm

60 N

12 V

40 W

Solution from INVENTUS

How does the Application from INVENTUS work?

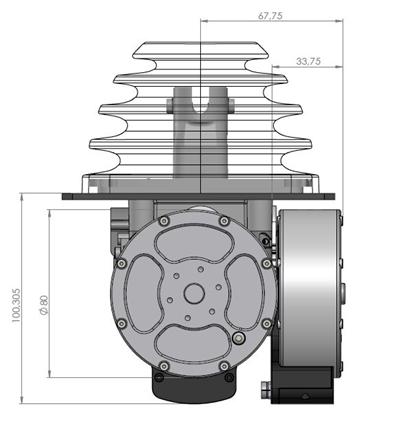

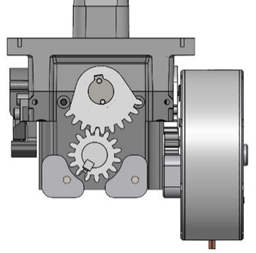

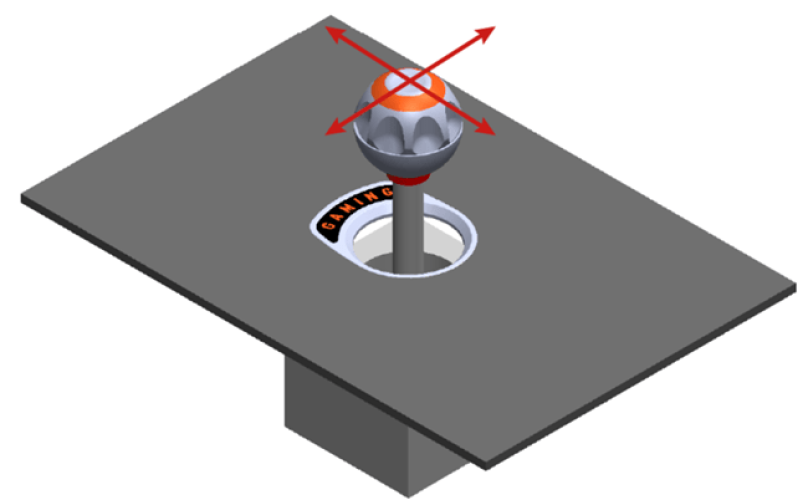

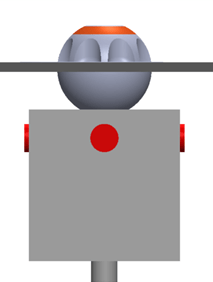

Docked to a mechanical universal joint and translated via a gear stage, INVENTUS equipped each of the joystick axes, which were rotated at 90° to one another, with an adaptive MR brake (detailed information on MR shear dampers) and was therefore able to passively control/brake both joystick axes independently of each other. The mechanical translation not only had the advantage of converting force but also made it possible to place the MR brakes entirely under the user interface.

The joystick can move freely within a certain range in the X and Y directions and always returns to the middle position thanks to the return springs.

Axis MR Brake

Joystick axis

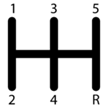

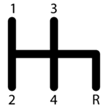

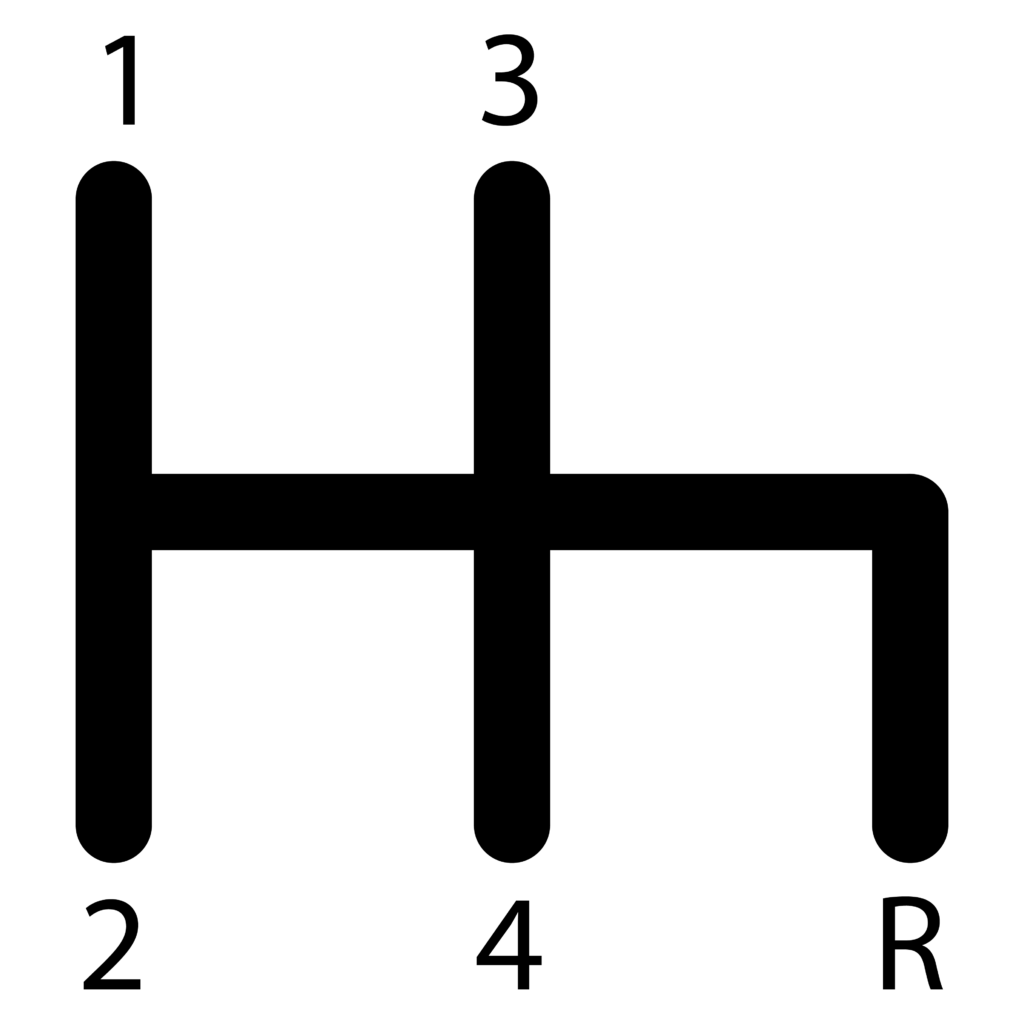

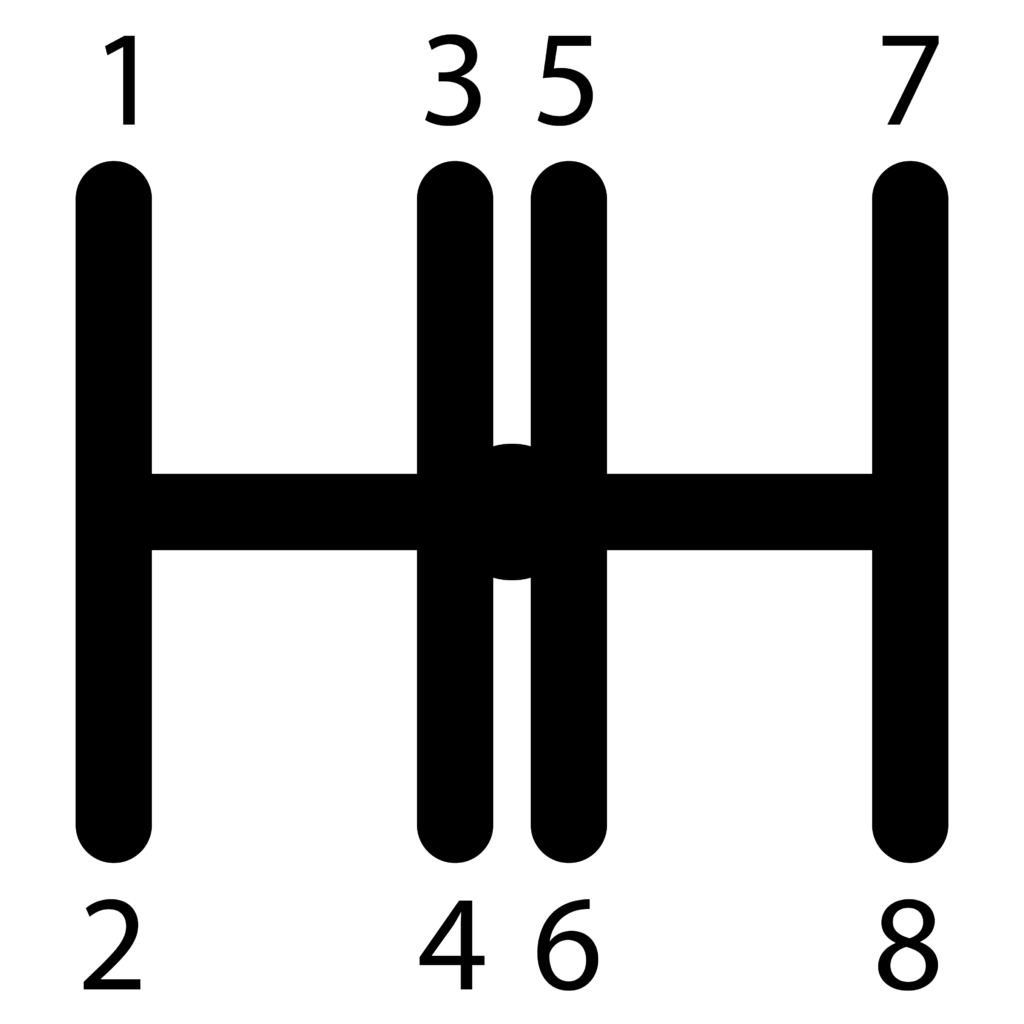

Inventus simulates “shifting”, i.e. the increased force when engaging a gear (crisp shifting) and guiding the lever within the simulated shift gates. The force curve (torque versus angle) can be individually adjusted using software. This makes it possible to replicate 4-speed, 5-speed, 6-speed, sequential or any other manual transmission. By replicating it is meant that only the switching paths listed can be used and the deviating range is blocked by the MR brakes – the MR brakes therefore also take on the task of the switching gate.

The stick is freely movable in X and Y direction, always returning to the center position due to the return springs.

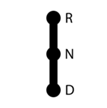

Sequential Shifting

X movement is locked

A wide variety of design options can be implemented in the vehicle, and space-saving combination options are also conceivable.

Comparison of state of the art/solution INVENTUS

The E-Shifter from Inventus offers the following advantages:

Due to the high locking torque of the MR brakes, the INVENTUS E-Shifter is very compact.

Due to the fact that INVENTUS MR brakes require significantly fewer raw materials such as copper, iron and rare earths compared to electric motors with the same torque, their manufacturing costs are considerably lower. The electronics costs are also significantly lower due to the much lower energy requirement. In addition, the technical design of an MRF brake is much simpler than that of an electric motor.

As the INVENTUS MR brakes have very low friction and clear advantages in terms of power build-up, especially at low speeds where the joystick is usually moved, the operator experiences a completely new driving sensation that cannot be approximated with electric motors.

The fact that actuating forces of up to 60 N are required at very low speeds predestines the INVENTUS MR brake for use and virtually disqualifies the electric motor for this application.

Thanks to the more effective operating principle of the INVENTUS MR brake and the higher power density, energy consumption is around 20 times lower than that of electric motor systems.

Prospect

INVENTUS will be happy to work with you to develop an adaptive joystick solution tailored to your adaptive joystick solution tailored to your application, whether in an e-shifter context or for another use.