Linear dampers

MR linear dampers various applications

INVENTUS has already implemented a wide range of special versions of the MR linear dampers. On the one hand, this is due to the fact that linear damper applications are widespread and, on the other hand, there are a wide variety of technical implementation options that are worth briefly introducing. In this context, the technical explanation of the MRX applications in linear flow mode briefly shows the examples of a linear damper with a permanent magnet in a knee prosthesis (more detailed information here) as well as the implementation of a linear damper with an external valve as a development tool for a furniture manufacturer (more detailed information on the results here).

In addition, the following specific MR linear damper developments follow under the heading Solutions from INVENTUS: InvShock for racing applications, fully adaptive bicycle damping and adaptive door dampers. This allows the reader to get a somewhat better idea of what options exist and what areas of application already exist.

State of the art

Classic hydraulic linear dampers

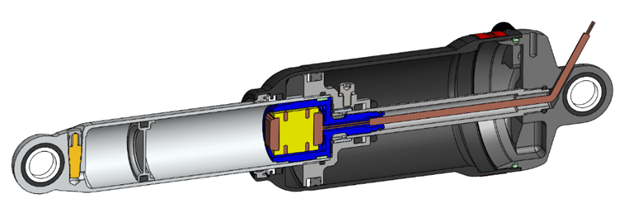

There are a number of different design options for the classic hydraulic linear damper. A piston is guided linearly in a cylinder and carries out a lifting movement in which a liquid, usually oil, is pressed from one side of the cylinder through a throttle gap to the other side. Depending on the throttle gap, a speed-dependent damping force is created.

The embodiments shown below show the most common different technical solutions. A key point is how the volume compensation (usually implemented in the form of a separated gas volume) is carried out, which compensates for the immersed piston rod, the temperature influences and the leakage. In the illustrations, the compensation is always shown on the pressure stage side, this does not necessarily have to be the case, depending on the desired force characteristics in combination with the given installation space, the respective technical implementation option is predestined, with the first two approaches of the single-tube construction as a pot construction and the two-tube damper certainly the most frequently implemented constructions are:

The design implementations listed are the same for MRF technology, only the valve is then based on the MRF effect.

Often, depending on the direction of movement, various valves become effective and then lead to different damping forces depending on the pull and push actuation, or throttles also become effective depending on the stroke, for example with end position damping.

In some cases, the throttle gap can also be adjusted mechanically and the hydraulic damper is then at least partially adaptive.

Adaptive hydraulic linear dampers

Adaptive hydraulic linear dampers are already state of the art and are implemented, for example, using the following 3 approaches:

Electric servomotors adjust the throttle gap and thus vary the hydraulic damping (e.g. prosthesis C-Leg from OTTOBOCK)

MRF solutions change the viscosity “virtually” in milliseconds and implement a fully adaptive system (e.g. Audi TT and Ferrari F430)

Fully active hydraulic systems have very powerful pumps that actively generate the forces (Porsche Panamera)

Solutions from INVENTUS

The following various MR linear damper solutions (detailed information here) from INVENTUS are discussed and their implementation is briefly described:

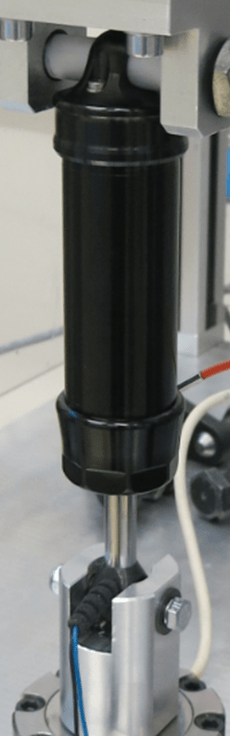

InvShock for racing application

In order to continue the testing and development of the MRF linear dampers, INVENTUS developed the InvShock damper system, which, tested and fine-tuned over many years, served an Inventus employee well in his racing activities in mountain races. The fully adaptive, real-time system helped him improve the overall performance of his racing car in hill climbs.

The following items were initially on the to-do list:

- Increased performance compared to conventional damper systems – through fully adaptive damper control/damper characteristics of the 4 individual wheel suspensions.

- Communication between actuators and control unit via CAN bus

- “Start mode” allows energy to be buffered by preloading the rear damper-spring element for better traction and acceleration at start-up

- The “brake detection mode” prevents the chassis from tipping forward and wheel load shifting, thus shortening the braking distance

- Real-time impact detection (<3ms) and front shock adjustments (10kHz rate)

- Temperature compensation system (oil viscosity) and overheat protection

- CAN logging of damper speed, travel, acceleration and recording these in histograms

The INVENTUS solution ultimately fulfilled the following profile:

Cylinder tube Ø:

Length:

Total weight:

Max. locking force:

Peak-to-Peak-Response time:

40mm

300mm (Eye connection distance)

1800g (including spring)

> 2kN @ 5W

< 5ms

Integrated displacement measurement with 1 µm resolution

Logging function (update frequency 10 kHz) of position/damper speed etc. via CAN, UART, Bluetooth or WiFi

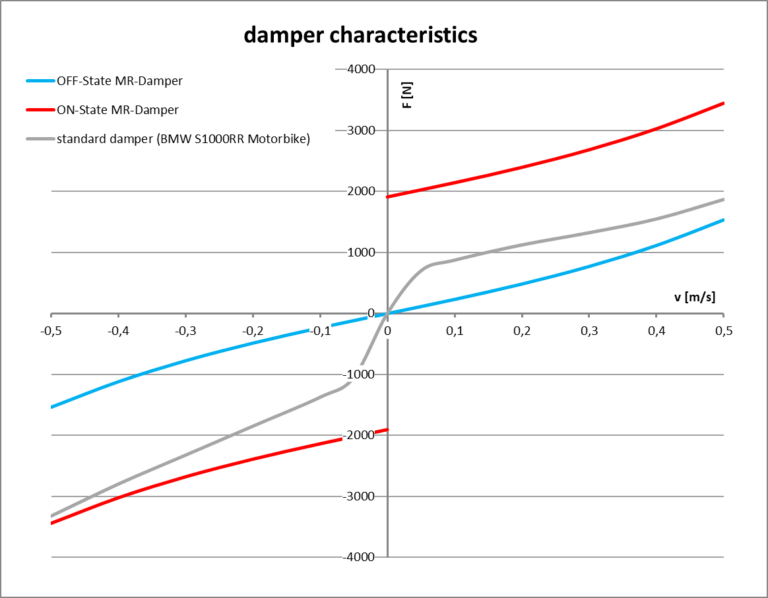

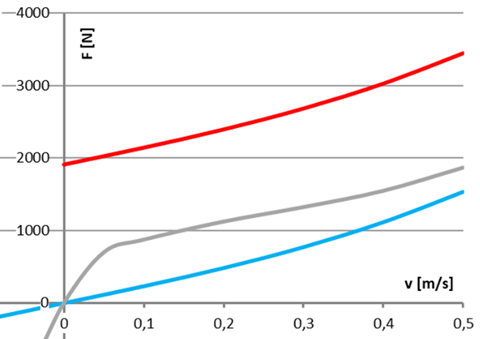

The diagram below shows the damping force of the InvShock in blue and red in the OFF and ON state area in relation to the previously installed damper with the characteristic curve shown in gray, you can clearly see how the working area has been expanded.

After testing the InvShock in over 30 mountain races, the performance was reduced by 1.5 seconds of racing time compared to the previous system.

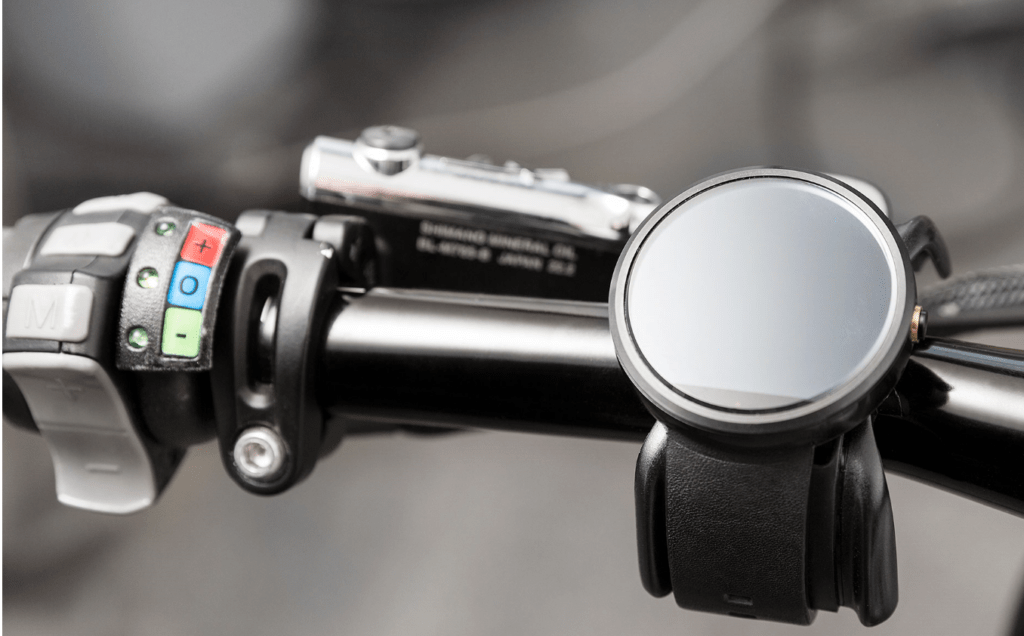

Fully adaptive bike damping

In collaboration with a renowned bicycle manufacturer, we developed an adaptive damper concept for the front and rear wheels. The following points had to be integrated into the implemented system:

- Variable end stops had to be implemented via software

- Background detection for dynamic damper adjustment through integrated sensors

- Real-time impact detection (<3 ms) and front damper adjustment (10 kHz rate)

- Pedal efficiency mode detects slopes and locks the rear shock (800 N at 0.5 mm/s)

- Up to 3 damper profiles can be saved and accessed via the control unit (customer requirement, although in principle any number could be displayed)

- All damping curves can be adjusted via an app on a smartphone

- Data readout option for e.g. damper speed, distance, temperature, etc.

Control unit

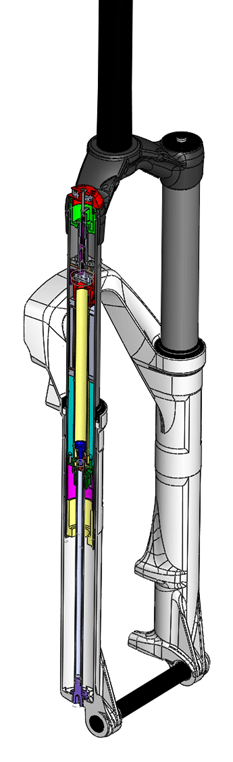

MRF suspension fork with integrated travel sensor

Electronics and power supply integrated in the frame

Rear wheel damper with integrated displacement sensor

Control unit

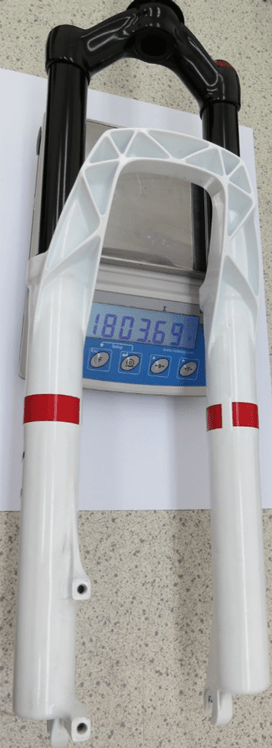

MRF suspension fork with key data:

- locking force: 660 N (at vmax)

- Stroke: 150 mm

- Cylinder tube-Ø: 35 mm

- Power consumption: 2 A (at max. 6,5 Watt)

- Total weight: 1810 g

- Design: Execution in existing Original suspension fork

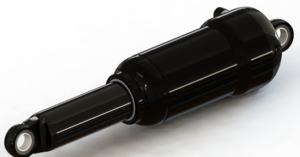

MRF rear wheel damper with key data:

- Max. locking force: 1.1 kN (at vmax)

- Stroke: 50 mm

- Cylinder tube-Ø: 27 mm

- Electricity consumption: 1,5 A (bei max. 5 Watt)

- Total weight: 300g

Adaptive door damper

Below, 2 implantations of an MRF linear damper are shown using 2 videos and visualized for the viewer. What options exist, for example, on an existing vehicle door and a room door to optimize comfort and safety – completely new operating concepts are emerging:

Comparison

Basically, the MR linear damper has the main advantage that the force is not only generated based on the hydraulic effect, but the MR effect also provides a large working range. The working area is defined by the two characteristics OFF-state (hydraulic effect) in blue and ON-state (hydraulic + magnethereological effect) in red (working area = area between OFF and ON state). Since the majority of the force effect is generated by the magnethereological effect, the basic hydraulic force and the associated temperature influence can be kept minimal, and the maximum force remains almost temperature-independent compared to purely hydraulic solutions in gray.

If you compare the MR linear damper with the purely hydraulic linear damper, it is clearly the working range and the simultaneous complete adaptivity with almost unlimited control options that speak for the MR linear damper.

If you compare the MR linear damper with other adaptive linear systems, the fast response and the comparatively simple technical structure are certainly a big advantage. Apart from the piston rod and cylinder tube, which are also required for purely hydraulic applications, the remaining functional surfaces are kept comparatively simple and, for example, do not have to be ground as is usual with hydraulic adaptive systems and gap dimensions can also be dimensioned and tolerated much larger. The MR system also impresses with its very low energy consumption.

Prospect

INVENTUS would be happy to work with you to develop an adaptive MR linear damper tailored to your application.