Adaptive Anti-Roll Bar

Semi-active system by INVENTUS

Stabilizer

After suspension and damping, stabilizers are the third basic component of the car chassis that determines driving behavior. Usually designed as elastic torsion bars, they connect left and right wheel carriers and limit the side tilt of the vehicle when cornering. By adjusting the stiffness of the stabilizers on the front and rear axles, it is possible to influence the wheel load distribution when cornering and thus the self-steering behavior. Stabilizers influence the suspension behavior, especially when driving over bumps on one side of the road, as they transfer the forces to the other side. The coordination is therefore always a compromise between the lowest possible body roll and good suspension comfort with alternating suspension. In contrast to passive wishbones, semi-active or active roll stabilization can counteract this conflict of objectives (roll refers to the tendency of a vehicle to torsional vibration around the longitudinal axis). The self-steering behavior can also be actively influenced.

State of the Art

Future vehicles will require new solutions::

The trend towards larger vehicles, especially SUVs, continues and is leading to taller and, in conjunction with electromobility, heavier vehicles. This results in an increased tendency to roll and pitch and leads to increased movements of the occupant’s head and upper body when changing direction, which can be uncomfortable and cause nausea. A rigid/hard stabilizer can help, but it significantly reduces driving comfort when driving over bumps on one side. Fully active chassis systems (e.g. Active Ride) solve this conflict, but are expensive and technically complex. Active electromechanical roll stabilizers from German suppliers are only available to a limited extent and are also technically demanding. Purely mechanical roll stabilizers have a working range that is too small and, due to fixed mechanical presettings, cannot adapt quickly enough to different situations, such as: B. a sudden sharp turn.

There is therefore a significant technical gap between a fully active suspension and a simple stabilizer bar, particularly in cost-sensitive mid-range vehicles and vehicles with limited installation space.

List of currently available stabilizers with a short technical description:

Is a mechanical torsion bar which connects the left and right wheel carriers of an axle with rubber mounts. If you drive a wheel over a bump, the quasi-rigid connection between the two sides causes the vehicle to swing up, and ride comfort suffers. On the other hand, the passive stabilizer is very simple, elementary in structure and is ideal for low-cost applications.

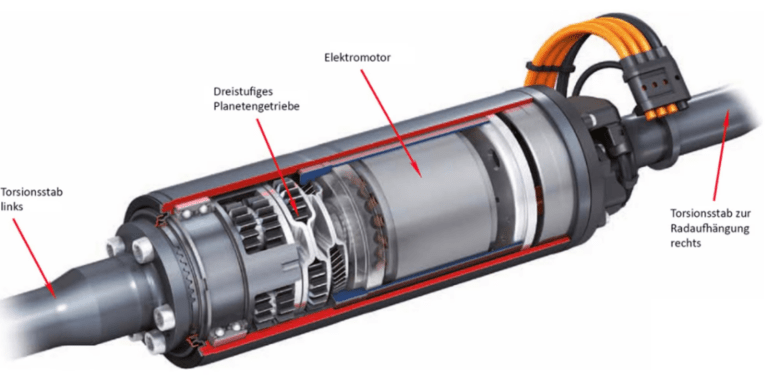

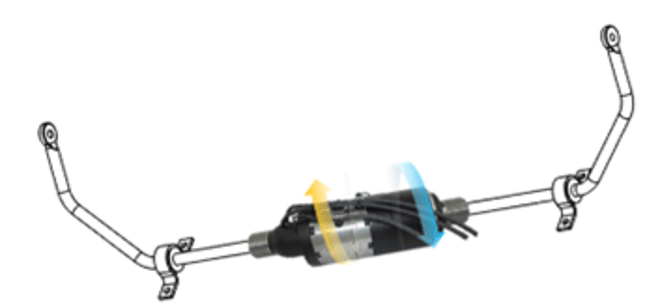

Active roll control systems intervene independently and generate an anti-roll moment in the event of a tendency to roll, thus stabilizing the vehicle and thus improving driving dynamics without impairing driving comfort. The technical implementation is that the torsion bar linkage is separated at one point and an electric or hydraulic drive is inserted in between (see Fig. 3). This technically very complex design is mainly used in the high-price segment.

In order to close the gap between passive and active stabilizers, coupling systems can currently be used to switch between torsionally rigid and torsionally soft, but these systems have not yet become established.

For the sake of completeness, the option of a completely fully active hydraulic chassis is listed here, in which all 4 wheels are individually controlled/damped via hydraulics. Stabilizers can be dispensed with completely, but this is an absolutely high-price application.

Requirements

In order to create a solution in line with the current market situation, especially in the mid-price segment, we developed an adaptive stabilizer that can be operated completely variably from torsionally rigid to torsionally soft.

Source: Hyundai

The following objectives had to be pursued:

Most of the functionality of the active roll stabilizer at 30% of its cost

Simple, robust design with great variability

Low energy requirements with operating voltages <12 volts, as well as low costs for all electronics

Very compact design (Due to the very limited space in today's cars, there is hardly any installation space, especially in the area of the front and rear axles.)

Implementation of a failsafe concept

INVENTUS developed the ATD1200 prototype based on the following technical data:

Maximum required torque (hard position): 1200 Nm at 60 watts (in the vehicle)

Outer diameter: 91 mm (similar to active solutions on the market)

Working angle: 20°

Vehicle: BMW X6 Type: F16 built in 2018

Installation situation: front and rear axle (stand-alone solution preferred for prototypes, later communication via CAN bus possible)

Solution from INVENTUS

How exactly does this application from INVENTUS work?

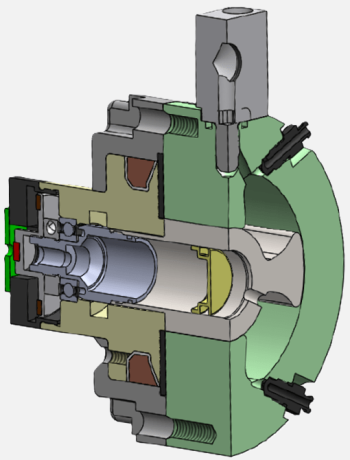

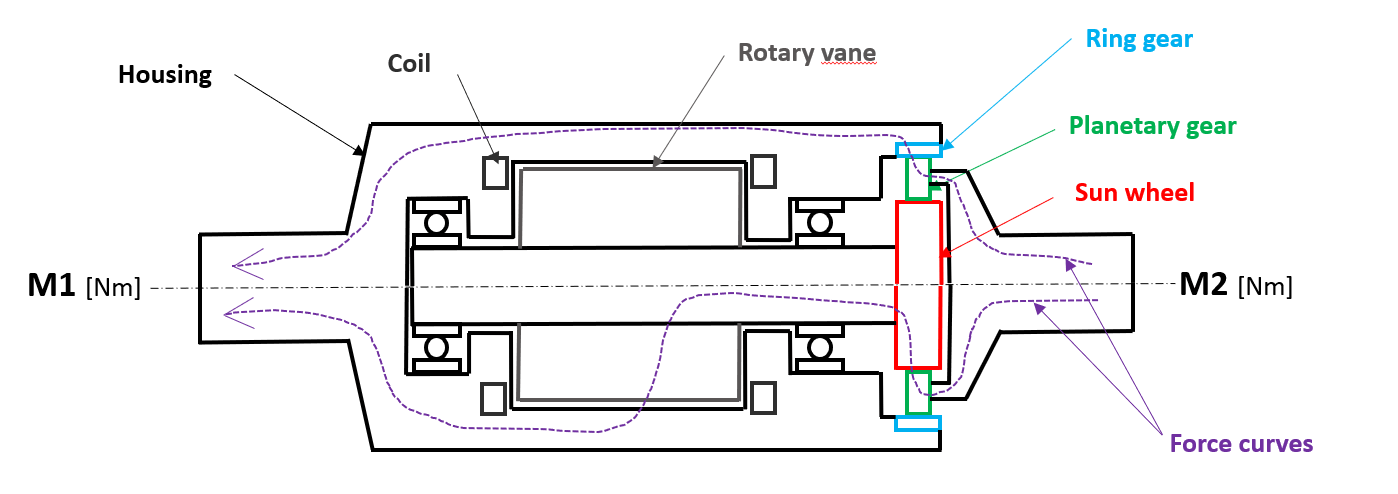

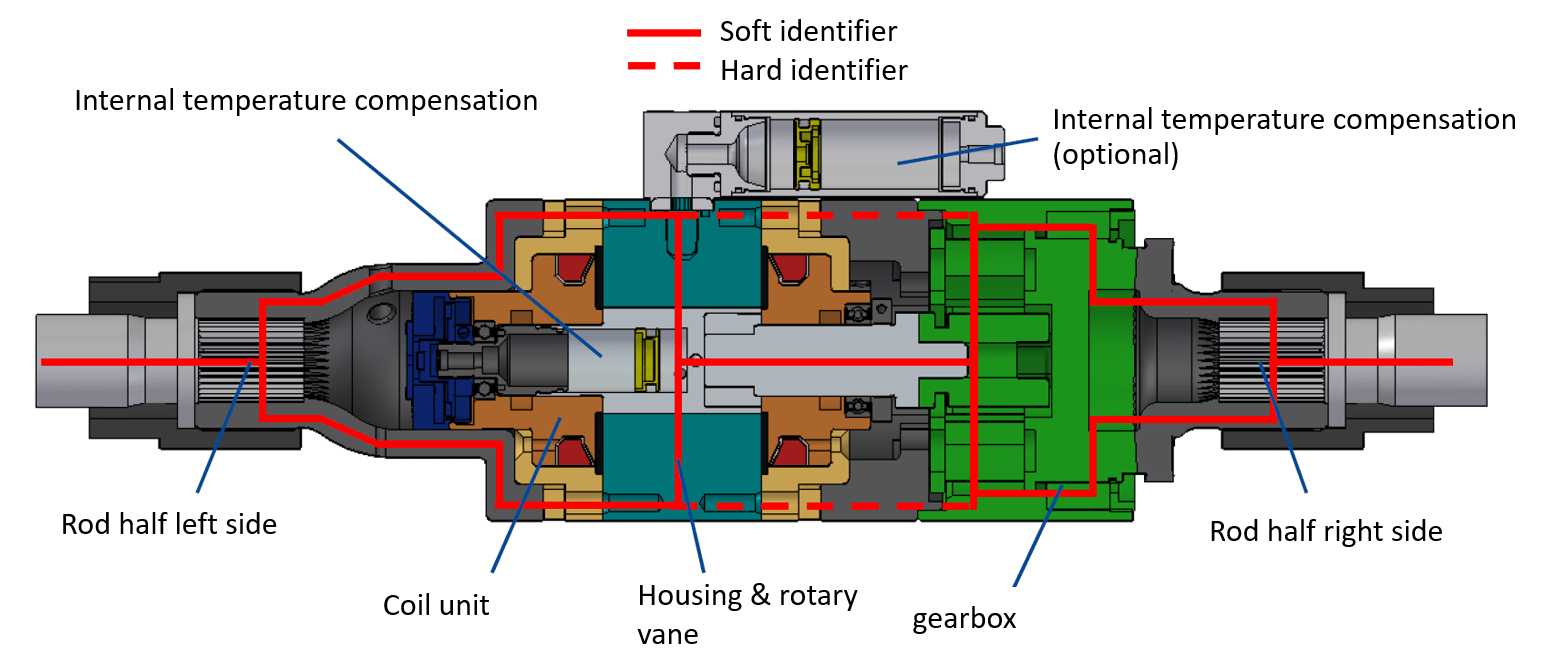

Based on existing active systems, we separated the stabilizer into two halves and integrated an MR rotational damper (detailed information about MR rotational dampers here). In order to build a correspondingly small diameter, we combined the MR rotary damper with one compact planetary gear set (see Fig.5).

The rotation damper ATD1200 (see Fig.6), implemented in the current solution as a 2-wing solution, achieves approx. 100° swivel angle with a maximum of 250 Nm locking torque (shown in Fig.7) and has the entire area marked in red as a working area, while switchable mechanical Solutions that are tied to corresponding characteristics or switching times can be regulated to any moment in the working area in milliseconds.

Operating range MR actuator ATD 1200

The adaptive stabilizer with gearbox and connection has the following additional characteristics:

Dimensions

∅ 91 x 193/204 mm

Weight of complete actuator unit

7500g (robust protoype)

Power supply voltage

12V

Rotation angle stabilizer (rod)

21°

Rotation angle actuator

100°

Max. torque (ATD1200)

250Nm

Max. torque stabilizer (Stange)

approx. 1200Nm

Max. torque stabilizer to ATD1200

approx. 5Nm

Max. operating pressure

120bar

Preload pressure

60bar

MRF volume

75ml

Temperature range

-40 <-> 120°C

Max current

5A

Power consumption

60W

Switching time (0-100%)

<30ms (at 12 volts)

higher volate => shorter switching time

In order to better understand how the planetary gear works, see the illustration below (Fig. 6), which shows the power flow in the adaptive stabilizer. It is clearly visible how part of the drive torque M2 of the web is introduced into the ring gear and the remaining portion into the sun gear. The ring gear contains the housing and the sun gear is directly connected to the rotary vane. The torque is transmitted from the web to the ring gear in two ways, once directly via the planetary gear and once indirectly via MRF hydraulics via the rotary vane.

The specific splitting of the force flow across the two branches as well as the resulting kinematics depends on the operating case, but one condition is set:

M1=M2 (action torque = reaction torque)

The working area in between is accessible through current supply at 0-100%.

Now the question certainly arises, why do I want to regulate the stabilizer behavior or vary it as desired?

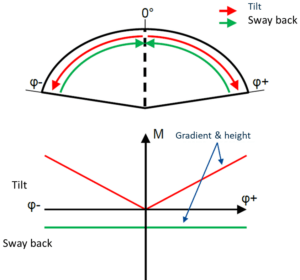

However, the continuous adjustment offers the following options, with the graphic showing the vehicle pivoting in in red and the pivoting back in green (0° lies in the plane of symmetry of the vehicle):

- A separate characteristic curve can be set for each direction for the angle ranges from 0°.

- This allows the oscillation and rollback characteristics to be adjusted independently of each other.

- This can be changed individually for each axle and depending on the driving condition.

- In addition to a linear characteristic curve that simulates a spring characteristic curve, constant torques and every conceivable characteristic curve can also be set within the actuator’s working range.

Comparison of the state of the art/solution INVENTUS

New generation driving experience:

The MR stabilizer automatically adapts to changing driving conditions and ensures maximum stability and comfort. Whether cornering quickly or on uneven roads, the MR stabilizer offers a tailor-made solution for all road conditions and closes the gap between high price and rudimentary mechanical solutions.

The adaptive technology of the MR stabilizer not only improves comfort and driving dynamics, but also optimizes the efficiency of your vehicle, as only a small amount of energy is required to lock in relation to active systems (active stabilizer or fully active hydraulic chassis).

Due to the simple electromechanical structure, the MR stabilizer has clear economic advantages, even in relation to purely hydraulic solutions, the system from INVENTUS is very simple and elementary using the MR sealing effect, which also has a positive effect on the tightness/lifespan and also the weight of the system affects.

The system ensures greater driving safety by dampening unwanted movements of the vehicle. At the same time, the MR stabilizer offers unprecedented driving comfort for a relaxed driving experience.

Prospect

INVENTUS will be happy to work with you to develop the ideal MR stabilizer system for your application, taking into account the prevailing boundary conditions.