Steer-by-Wire

Force Feedback Actuator Hybrid Solution

Steer-by-Wire describes a steering technology for vehicles that completely dispenses with a mechanical connection between the steering system and the steered wheels.

Electromechanical actuators on both the steering wheel and the wheels enable the driver’s intuitive steering signal to be transmitted to the wheels and the driving experience, e.g. impacts on the wheels, to be perceived haptically on the steering. A control unit is responsible for communication from the steering to the wheels and vice versa by means of various sensor signals.

This new „software-defined“ mode of vehicle operation requires new types of actuators whose features and functions are mainly enabled by software. This enables the use of new technologies – INVENTUS is developing a very compact steering-related steer-by-wire force feedback actuator (following SbW FFA) based on its cutting-edge technology.

The system is characterized by minimal space requirements, lower costs, higher performance, safety and reliability.

We are now looking for partners to bring this ground-breaking steer-by-wire technology to the market.

State of the art

Current SbW technologies close to the steering wheel are based on electric power steering, direct drive and belt drive systems at various positions on the steering column or steering wheel.

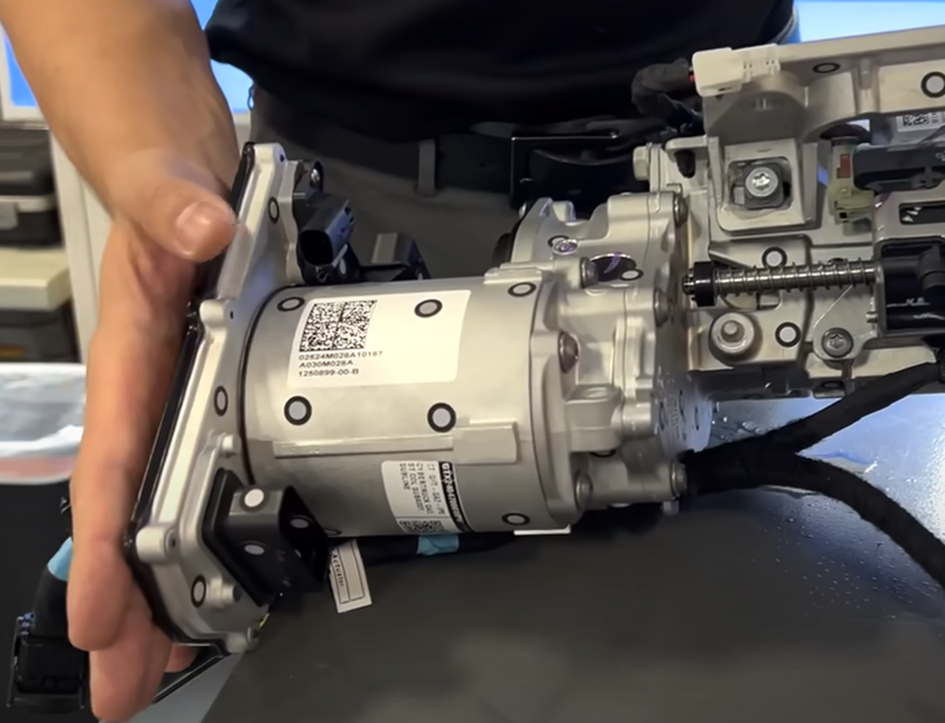

At the time of the SbW FFA Generation 1, only the combination of electric motor and reduction gearbox/belt drive was technologically possible and feasible in series production. The following illustrations show the SbW FFA of the Tesla Cybertruck, which was state of the art at the time. It is noticeable that the steering torque is always transmitted via the long sliding/sliding shaft with sometimes double telescopic shafts (for stowable steering columns with more than 150 or 250 mm travel length) and is only then picked up by a drive motor. The motor is located more than 500 mm away from the initiation and protrudes into the cockpit interior, as the aforementioned sliding shaft, bearings and support structures require corresponding space. In addition, the directness of the steering suffers from the long transmission distance, all softness/play/friction is superimposed, while at the same time the complexity and susceptibility to faults increases.

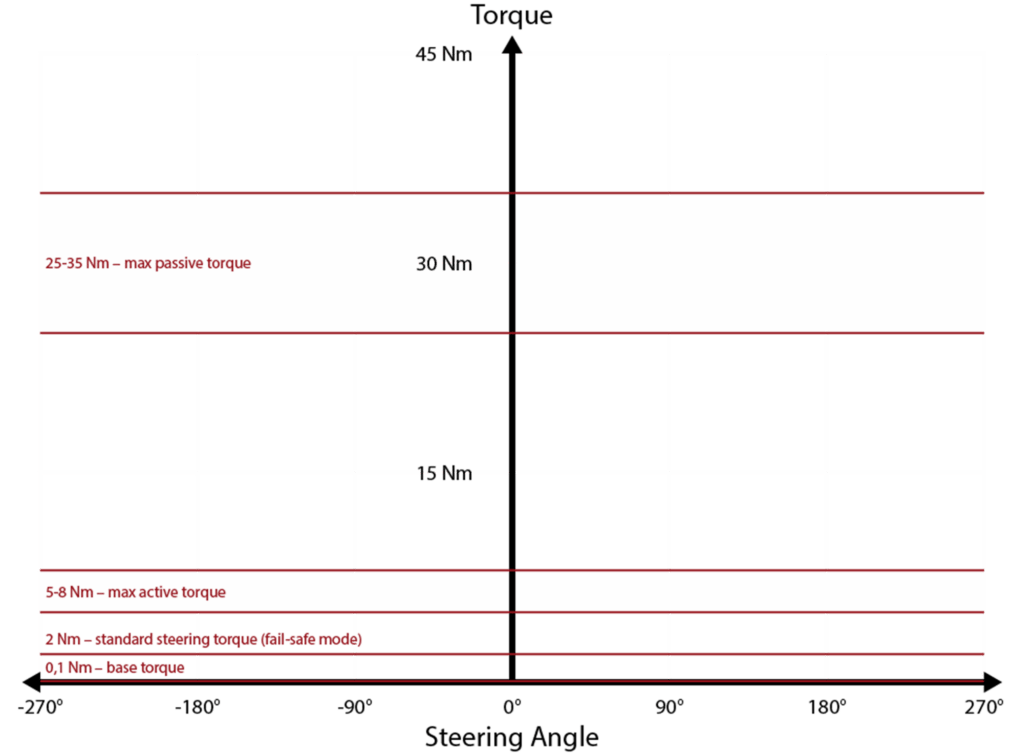

In normal driving mode, >80 % of the steering movements are passive torques, as most maneuvers are quasi-static or very slow.

The use of redundant electric motors for braking, especially at very low speeds or even at standstill, is very inefficient, as the electric motor requires high currents and, above all, generates power loss (heat). The mechanical conversion of the rotational speeds does not really solve the problem either, as the high end stop torques have to be generated almost statically.

When driving in SbW mode, the force feedback perceived by the driver is made up of around 80 % braking torque (up to 35 Nm) and active feedback of 6-8 Nm (approx. 20 %).

While state-of-the-art steering actuators are predestined for active feedback, it is often the high level of braking torque in the static state for which modern SbW systems are not optimized.

This results in conflicting objectives in terms of:

... the haptic/force feedback (play/softness of the entire steering column and the cogging torque of the electric motor - perceived ripple)

... of the required installation space

... of the total system weight

... efficiency

... the fatigue strength due to thermal overload

Requirements

As a basis for the development of our force feedback actuators (steer-by-wire drive + brake), the following basic technical data was used as a guide for intuitive and reliable steering operations during driving:

Solutions from INVENTUS

The analysis of the current situation with the high drive costs and the fact that a 4x higher torque has to be provided passively than actively suggested implementing a very compact, approx. 4x weaker motor (e.g. max. 8 Nm) and combining this with a powerful MR brake. To meet this challenge, we combine the advantages of active steering systems with our many years of experience in MR technologies and our high-performance brake systems.

How exactly does this application from INVENTUS work?

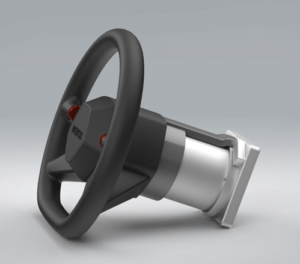

We are rethinking the hybrid solution the INVENTUS SbW FFA and flange it directly to the steering wheel, as it is much easier to process the torque directly and immediately where it is generated, namely directly on the steering wheel, and thus implement the steering haptics as directly as possible. However, this is only possible if the force feedback actuator is very compact and not too heavy or does not require too much power (due to the power cable cross-sections, which would otherwise impair the length and height adjustment).

Wickelfeder

E-Motor

Elektronik

MR-Bremse

The illustrated side view shows such an installation of the Force Feedback Actuator close to the steering wheel, in which a coil spring provides electrification immediately after the steering wheel, followed by the MR brake from INVENTUS, which brakes the system, and finally the electric motor that drives the entire system and the electronics that control it.

The MR brake is designed as an MRX shear damper with (detailed information) and generates 25 Nm (end stop torque) at 4 A and 12V within < 10 ms and has a very large operating range due to the low basic torque of approx. 0.1 Nm, which is haptically very „defined“ and direct according to the technical design.

The sensitivity of the steering can be optimally adapted to the respective customer requirements.

The approach of a uniform standardized steering column makes considerations such as symmetrical bodies conceivable without future differentiation between left- and right-hand drive vehicles.

The following two concepts show modifications of the steering wheel installation shown above. In Concept I, for example, the winding spring can be dispensed with due to the limited angle of rotation range, while Concept II manages completely without an electric motor by using a return spring for the reset and dispensing with active feedback.

MR-Bremse

E-Motor

Elektronik

Wickelfeder + Rückstellfeder

MR-Bremse

Elektronik

Of course, we have also thought about length and height adjustment, impact absorption and cable routing.

If the customer does not wish to install it directly close to the steering wheel, the INVENTUS SbW FFA can also be implemented with a diameter of 60-100 mm (e.g. directly in the steering column), but it is then simply longer in order to achieve the desired specifications.

Comparison of the state of the art/solution INVENTUS

The steer-by-wire brake from Inventus offers several advantages:

The combination of a small electric motor and a powerful MR brake (magnetorheological brake) = Hybrid Direct Drive (HDD) enables a very compact design. The following illustrations show flange-mounted to an existing standard steering column in comparison how large the hybrid solution from INVENTUS would be in relation to an electric motor without mechanical transmission in order to meet the required torque specifications (Fig. 9 and 10) – Both solutions therefore show complete solutions including steering wheel adjustment and safety systems:

1 Nm of braking torque costs significantly less with an MR brake than with an electric motor. This is due to the fact that, compared to an electric motor with the same torque, the INVENTUS MR -brake requires significantly fewer raw materials such as copper, iron and rare earths, which is drastically reflected in the manufacturing costs. In addition, the technical design of an MRF brake is much simpler than that of an electric motor.

This fact makes it economically viable to implement the combination of an MR brake and an electric motor in our INVENTUS SbW FFA, as the size of the motor can be significantly reduced. In our specific case, the electric motor then only has to deliver 1/4 of its original torque and this not only reduces the costs immensely, but also simplifies the entire connection, cabling and the electronics behind it. The necessary additional MR brake can be purchased relatively cheaply and offers various advantages at the same time.

By integrating this technology (Hybrid Direct Drive), vehicle manufacturers can save around 20 euros on the SbW FFA and a further 10 euros on the control unit. It is assumed that manufacturing costs in the low double-digit euro range can be expected for medium quantities of the 25 Nm-MR brake.

Due to the direct installation of the INVENTUS SbW FFA on the steering wheel and the haptically high-resolution and defined MRX shear damper, the driver experiences a completely new driving sensation that cannot be reproduced with the current state of the art.

The Hybrid Direct Drive solution requires significantly less installation space than the state of the art and therefore offers more design flexibility, as it is suitable for head-up displays, retractable steering wheels, left-hand and right-hand drive vehicles. This makes it possible to standardize the steering column for different vehicle types (uniform steering column). In addition, completely new realizations of steering adjustment or stowage are also possible.

The MR brake can efficiently generate a braking torque of up to 35 Nm and thus enables precise and reliable feedback on the steering wheel (end stops; steering wheel grip when getting on and off the vehicle; wheels on the kerb). The area of application at very low speeds almost disqualifies the electric motor for providing high passive torques.

Thanks to the more effective operating principle of the INVENTUS MR brake and the higher power density, energy consumption is more than 20 times lower than that of electric motor systems.

The combination of a small electric motor and a highly effective MR brake ensures excellent thermal heat management, which significantly increases the durability and reliability of the system.

Possibilities

The new software-defined operating mode of vehicles is shown here using various operating modes, whereby the MR braking torque adapts variably within milliseconds with an extremely low power consumption of 4.2 amps / 60 watts (at 12 volts) and locks up to 25 Nm in <20 ms.

The INVENTUS SbW hybrid system can change the braking behavior and thus the perceptible steering behavior in real time. The possibilities for storing various characteristics are almost limitless; the following illustrations show various analytical approaches:

Take a look at the following videos to better understand the adaptive force feedback of our system:

Fail Safe – Functional safety according to ISO 26262

Functional safety is of great importance for all steer-by-wire systems. To ensure proper and safe operation of the INVENTUS SbW FFA hybrid system even in the event of a fault, two fail-safe options are available:

Option 1 – Battery solution

- To generate a fail-safe drive torque of 1 to 3 Nm (<1 watt), we also use a small battery

- Unlike conventional SbW solutions based on an electric motor, the INVENTUS system does not require sensors to detect the direction of rotation

- This means that the INVENTUS SbW system can be operated over a longer period of time with just a small battery, an accumulator or a capacitor

Option 2 – Permanent magnet solution

- We supplement the SbW MR brake with a permanent magnet in the magnetic circuit, which generates a magnetic field without a power supply – e.g. 2 Nm fail-safe drive torque

- During normal operation, this permanent torque can be canceled by counter current (-) or increased by current in the same direction (+)

- Our customers confirm that our MR brakes with permanent magnets offer a major safety advantage over other solutions on the market, significantly simplify the safety architecture (in accordance with ISO 26262 and ASIL A to D) and save costs at the same time

Prospect

INVENTUS would be happy to work with you to develop the INVENTUS-SbW FFA actuator tailored to your application.

Cooperations

In addition, we were a cooperation partner in the project „Steer-by-Wire with a magnetorheological feedback actuator“ with MdynamiX and the Munich University of Applied Sciences.

We have also developed a magnetorheological steer-by-wire feedback brake for the Institute for Driving Assistance and Networked Mobility (IFM) in Kempten.

Here you can find the potential analysis of a steer-by-wire force feedback actuator with direct drive electric motor and MR brake.

Presented by Mr. Matthias Niegl at the chassis.tech plus 2024 in Munich